ClearVisionManufacturing

ClearObject creates custom Vision AI solutions to automate and augment manufacturing operations. The ClearVision Analytics Engine captures image data from the production floor and provides actionable analytics to drive continuous improvement.

Vision AI Solutions are customized and optimized to:

-

- Improve Quality

- Increase Efficiency

- Reduce Waste

- Optimize Operations

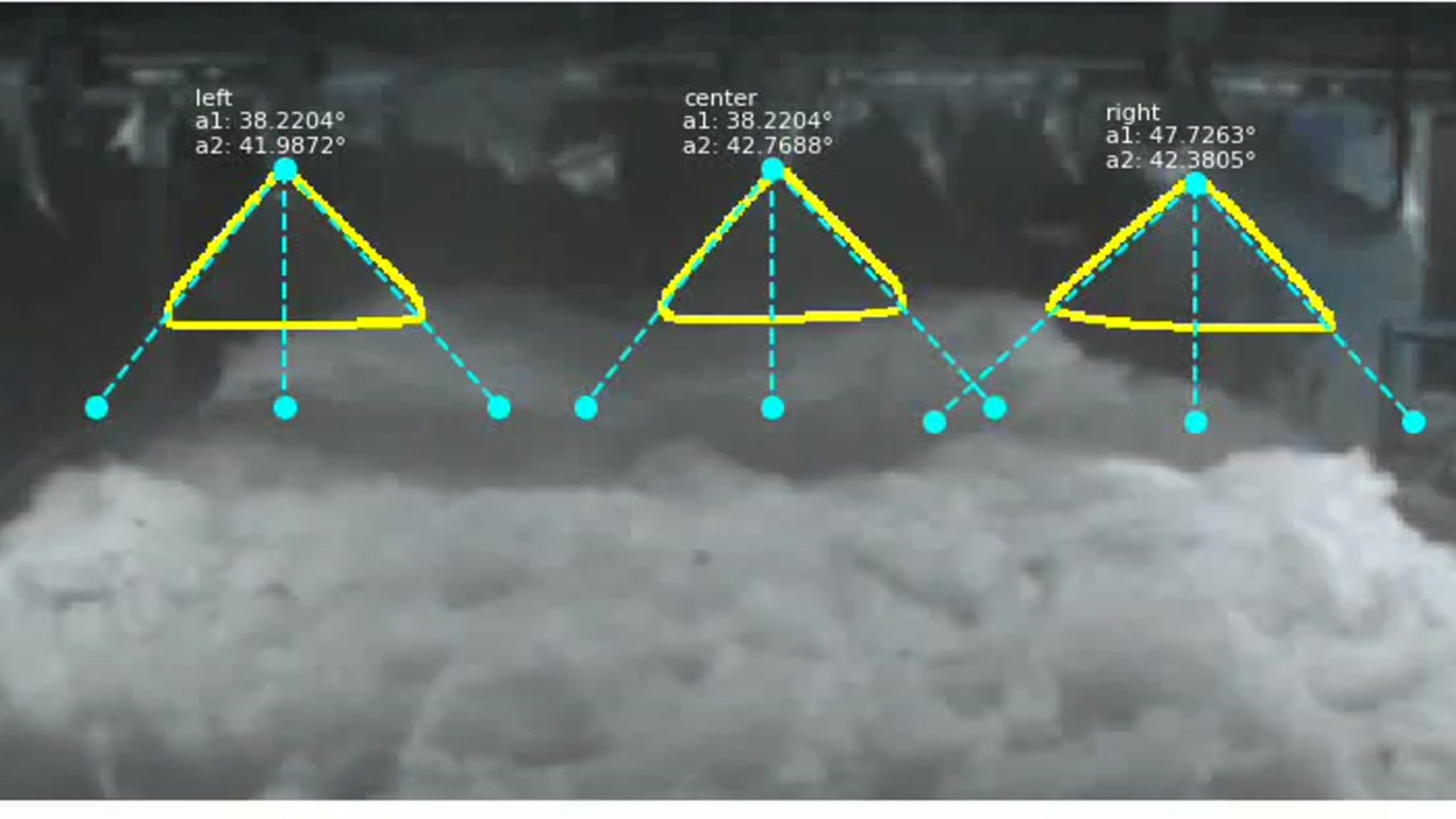

Clearvision measures the angle of spray and validates full adhesive coverage across the product

ClearVision: Vision AI Solutions for Manufacturing

Vision AI from ClearObject is a key part of the Factory of the Future, using vision data to make manufacturing more efficient, safer, and more profitable with solutions designed for specialized environments. ClearVision can automate tasks from mass-production lines to small-batch custom assemblies, helping you deliver what is promised while reducing inaccuracies and labor costs.

If you can see it, we can automate it.

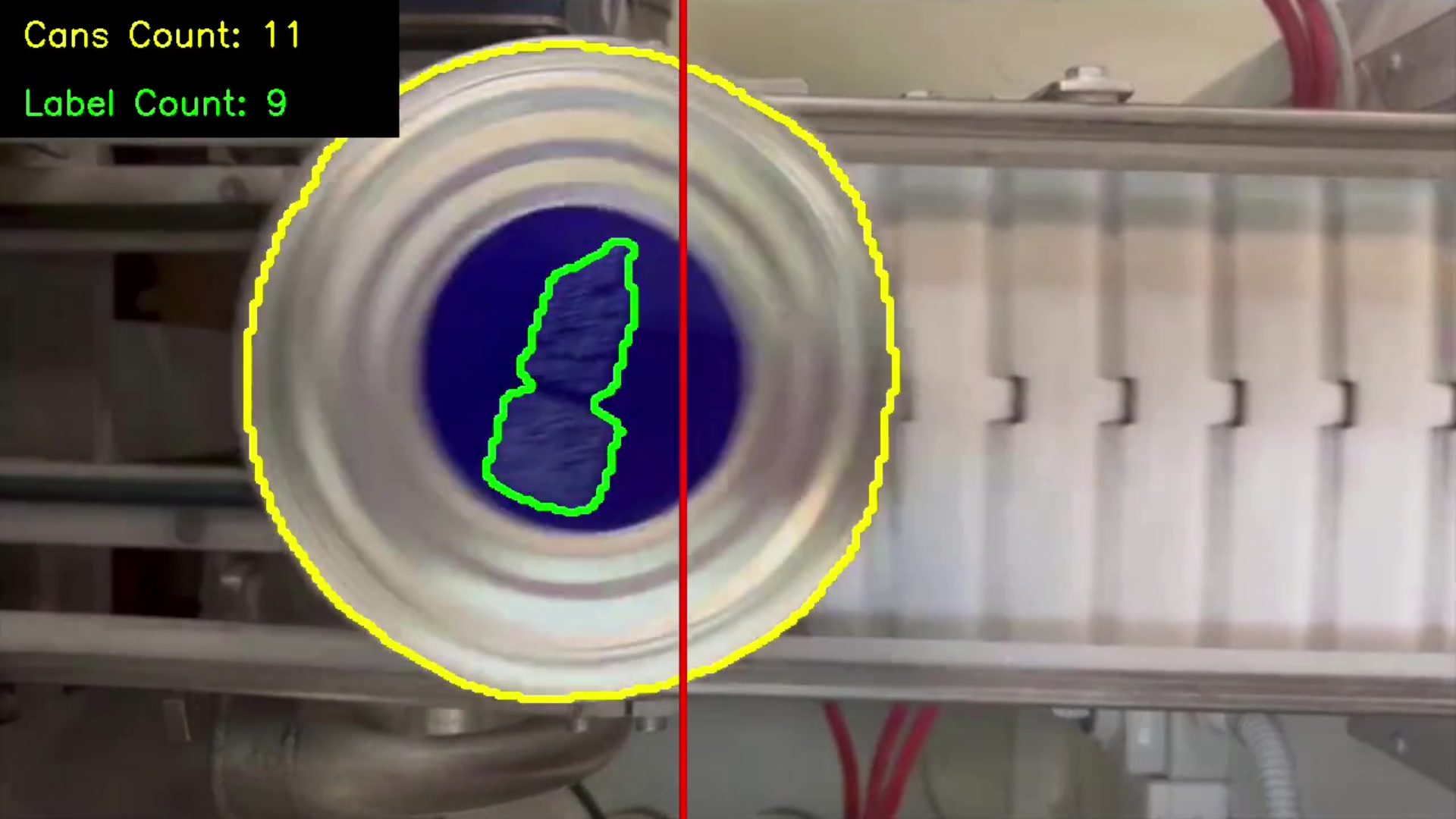

Vision AI identifies damaged containers and calls out missing labels in real time for immediate correction

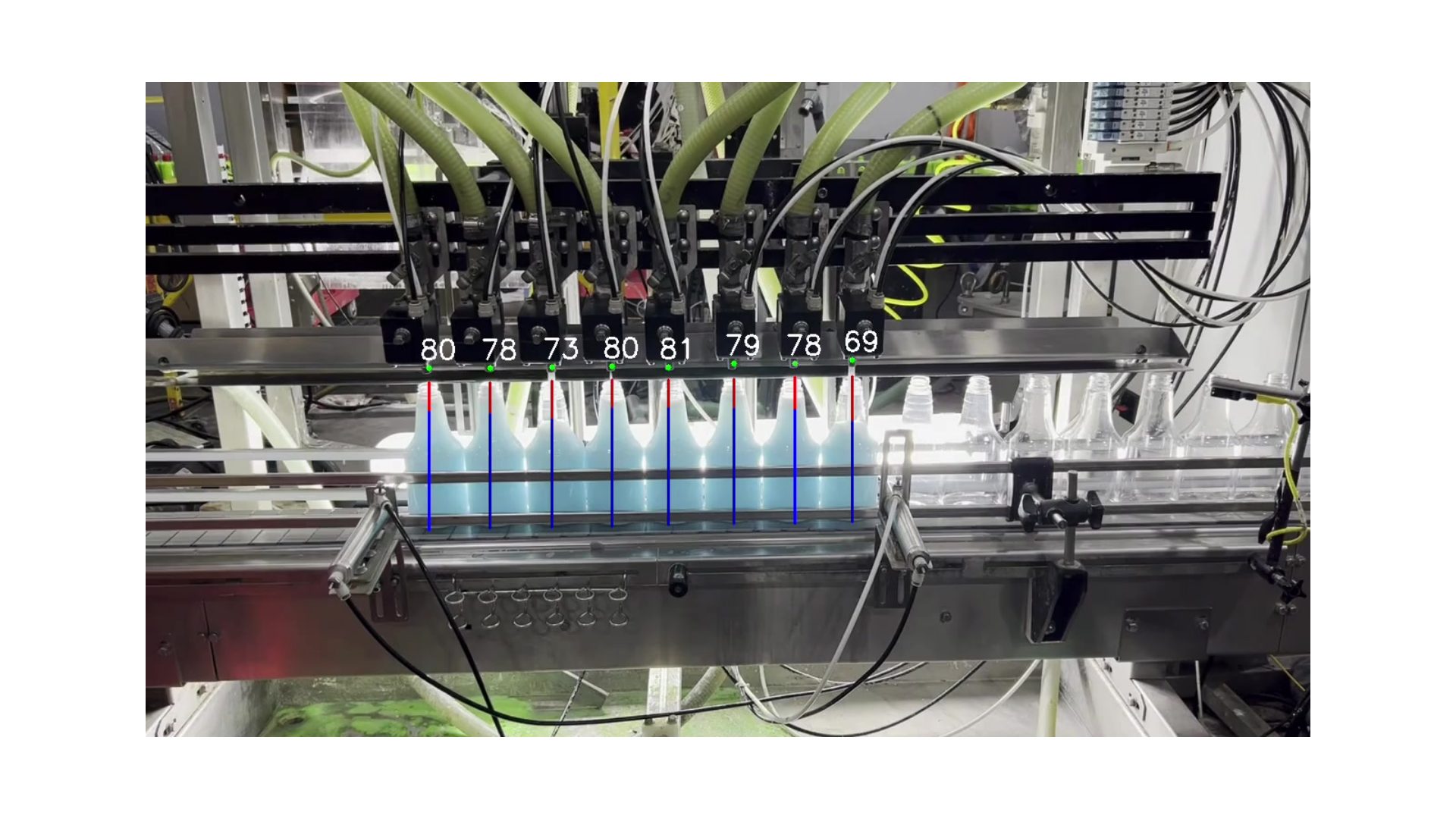

Fill volumes are monitored and communicated to the PLC to prevent underfilling and overfilling

Vision AI ensures strands are correctly fed for polymer composite coverage

ClearVision monitors the distribution spray volume and coverage of adhesives, ready to alert workers when errors occur

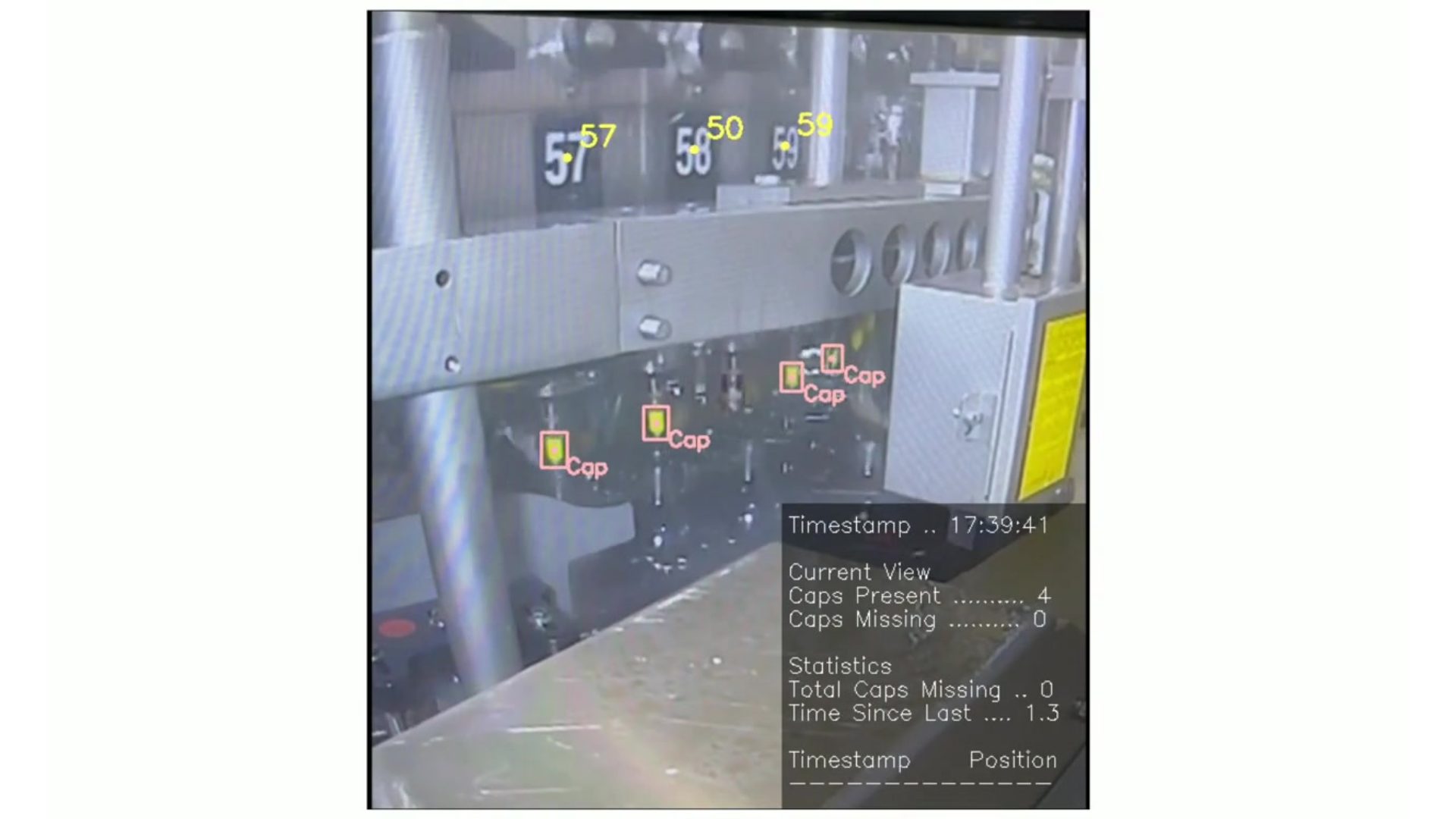

ClearVision Vision AI identifying missing or damaged vent tubes in a bottling facility.

Vision AI ensures consistent preparation of granite surfaces by tracking flame intensity, cooling, and line speed

Knauf Improves Quality and Safety

ClearObject, a Google Cloud Premier Partner, is excited to present ClearVision demos at Next 2025.

Find us in two locations. Google's Public Sector booth, showcasing how the ClearVision Inference Engine turns videos from highway cameras into valuable data to protect critical infrastructure.

The Google Hardwareverse area will feature demos on how ClearVision can improve manufacturing outcomes with improved quality control and process efficiencies.

ClearVision Benefits

Vision AI solutions by ClearObject turn today's production lines into tomorrow's factory of the future

Quality

Vision AI deployed at the edge provides real-time analysis to identify defects and eliminate false-positives, improving both quality and efficiency.

Efficiency

ClearVision reduces downtime and increases throughput with insights into operations. Lines run faster, longer, and with higher accuracy than those monitored by human eyes.

Profits

Reduce waste, cut labor costs, increase throughput, and minimize downtime so QA professionals can focus on solving quality concerns, not on monitoring the lines.

Safety

ClearVision Inference Engine will identify PPE violations, monitor hazardous work areas, and reduce emergency shutdowns to increase worker safety and keep operations running.

Simple

ClearVision integrates seamlessly into your existing systems, and can often use images from existing cameras.

Vision AI and Generative AI: Better Together

Vision AI solutions capture and structure data based on rules-based and deep learning models. Generative AI (GenAI) can then be used to interpret that data, place it into easy-to-read charts and graphs, and answer questions from the floor to offer potential fixes to any variance. GenAI maximizes the impact of your data without running complicated queries.

ClearVisionIn Action

Vision AI from ClearObject helps our customers solve complex problems efficiently, accurately and cost-effectively. Our systems already help businesses and governments inspect for damage, optimize processes for higher quality, monitor and interpret traffic patterns, and alert officials in times of need.

ClearVisionIn Action

Vision AI from ClearObject helps our customers solve complex problems efficiently, accurately and cost-effectively. Our systems already help businesses and governments inspect for damage, optimize processes for higher quality, monitor and interpret traffic patterns, and alert officials in times of need.

How It Works

Vision AI from ClearObject helps our customers solve complex problems efficiently, accurately and cost-effectively. Our systems already help businesses and governments inspect for damage, optimize processes for higher quality, monitor and interpret traffic patterns, and alert officials in times of need.

Capture

Record data from existing or new cameras and sensors optimized for your business requirements and operating environments.

Curate

To make sense of the captured data, Data Scientists build customized categories based on your specific use cases.

Label

ClearObject best practices, including working with customer SMEs, ensure the highest quality annotations are used to create the most accurate models possible.

Validate

Data Scientists will partner with customer SMEs to confirm that all categories and data labeling are accurate and aligned with business needs.

Train

Once accuracy is confirmed, our experts will design and train a highly customized AI model for your specific use case.

Deploy

Launch the new AI model and train staff on how to interpret the visualized dashboard of operational data.

Iterate

Continually iterate on the AI model to adjust for new learnings, optimizations, and changing business requirements.

ClearObject Offers End-to-End Support

Data Visualization

ClearVision overlays video images with real time analysis based on highly-trained AI models for your specific needs. GenAI can be layered to help workers understand the analysis and how to improve production using natural language.

Customized AI Models

ClearObject Data Scientists build and train a bespoke AI model based on your unique business requirements. We won’t force you into an existing model, we’ve built our reputation on listening to our customers and understanding their needs.

Deep Deployment Expertise

Our experts have years of experience in deploying vision systems and models on the edge including in some of the toughest operating environments imaginable. Once running, we continue to work with your team for continuous improvement based on learnings.

Hardware Recommendations

Integrate existing cameras and sensors into a Vision AI system, or work with ClearObject Experts to determine the optimal configurations for your environments. We help get you stared with the right set up for you.